What is bamboo pulp?

Source: Publish:2022-04-04

Bamboo pulp is a type of paper pulp. It is made from moso bamboo, phyllostachys pubescens, sinocalamus affinis and other bamboo materials, and is usually prepared by the sulfate method and the caustic soda method. There is also de-greening of tender bamboo and pickling with lime to make a semi-clinker. Fiber morphology and length, intermediate between wood and grass fibers. Easy to size, bamboo pulp is medium length fiber pulp, fine and soft. Pulp tensile bulk, high tear, low burst strength and tensile strength. Have high mechanical strength.

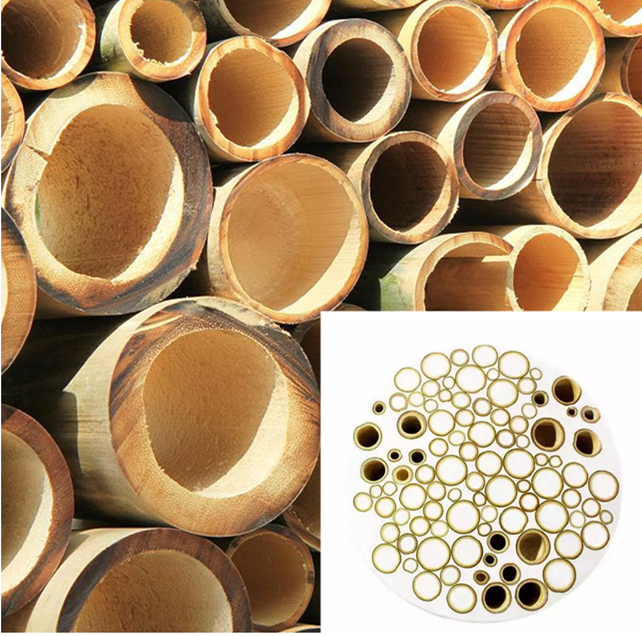

Cell Wall Structure

Bamboo fiber has two cell wall structures, one is multi-layer structure, the fiber wall is composed of wide and narrow layers alternately, the wide layer and the narrow layer each account for about 4 to 5 layers, and the wide layer is lighter in color, indicating that the wood is woody. The density of the element is lower. The narrow layer is deeper, that is, the density of lignin is higher. This type of fiber mainly exists in the peripheral part of the vascular bundle, accounting for about 1/2 of the total number of fibers. Another type of fiber cell wall is very thick, the cell cavity is narrow, the inner layer of the fiber secondary wall is mainly composed of two broad layers, and the outer broad layer is much wider than the inner broad layer. From the electron microscope pictures stained with potassium permanganate, this fiber is more colored than the former multi-layer structure type. That is, the degree of surgicalization is low, and they mostly exist in the middle of the fiber group of the vascular tissue. The pits on the bamboo fiber wall are much less than that of the needle fiber, and the pit openings are small, so the penetration of the liquid medicine is slow in cooking. in bamboo. Cell corners often form vacancies, especially among parenchyma cells.

PROPERTIES

At the beginning, the initial wet tensile index and cumulative work of rupture increased with the increase of freeness, but when reaching a higher freeness ( 55 SR ), the beating degree continued to increase, and the initial tensile index and cumulative work The rupture work decreased instead. In the case of higher beating degree, the fibers are excessively cut, which affects the effective entanglement and interlacing between fibers, resulting in a decrease in the initial wet tensile index of bamboo pulp. The secondary length of the wet paper web is formed by the fiber network elasticity of the pulp and the resistance of the fiber slippage. It is related to the average length of the pulp fiber, the fiber curl index and the adhesion of the wet paper web. The average fiber length is the basis of wet web elongation. When the beating degree is greater than 5 5 S R, the degree of internalization of bamboo pulp fibers will increase.

Pulping

HY Cut fin---It is suitable for partial free-form beating, and it can quickly reduce the wet weight of long fibers in the state of low power consumption, which is beneficial to improve the evenness.

HY Broom fin---It is suitable for viscous beating, and has a strong effect on fiber splitting, which is conducive to the improvement of beating degree.

HY Soft fin---Suitable for short fiber pulp, the cutting effect is weak, the fiber length is maintained, and the wet weight loss is reduced.

HY Ease fin----It is suitable for multiple pulp species, with strong decoupling and pumping ability, reducing power consumption and improving yield.

Application

Papermaking

Papermaking with bamboo fiber began in the Tang and Song Dynasties in China, and has a history of more than a thousand years, with rich practical and theoretical experience. Paper made of bamboo pulp has strong bones and a crisp sound. Bleached is used to make offset printing paper, typing paper and other high-grade cultural paper, and unbleached can be used to make packaging paper, etc. It can also be mixed with wood pulp in a certain proportion to be used in insulating paper such as cable paper, and cement bag paper.

Tableware Molding

New achievements; food and beverages made of bamboo fiber have high whiteness and tightness, good temperature and oil resistance, non-toxic and tasteless, can be completely degraded within three months, no three waste pollution in the production process, and greatly low production cost . For example, in JXD's tableware factory in Sichuan, China, this kind of green tableware made of bamboo fiber has already appeared, which has created excellent conditions for the development of the emerging environmental protection industry.

Fabrics

Bamboo fiber is divided into original bamboo fiber and regenerated bamboo fiber) using bamboo as raw material, through special high-tech processing, the cellulose in bamboo is extracted, and then the regenerated cellulose fiber is produced by making glue, spinning and other processes. Because the growth of bamboo does not require the application of various chemical fertilizers, it can also produce negative ions and anti-insect and antibacterial effects.

Bamboo fiber adopts high-tech means in the whole process of manufacturing and does not contain any chemical additives. It has excellent characteristics such as good air permeability, instant water absorption, strong abrasion resistance, and good dyeability. At the same time, bamboo fiber has natural antibacterial, antibacterial, anti-mite, deodorant and anti-ultraviolet effects.

View JXD ' S Bamboo Fiber Products